- Chapters

-

Chapter 4

Sections - Chapter 4 Home Page

- Chapter PDF

Chapter 4

Quick Links

Section 4.2

Common Approaches to Managing Transportation Assets

All infrastructure assets are designed to have a certain functional service life. However, there are major differences in how assets deteriorate (physically or in performance), the available treatment options to address deterioration, and different levels of consequence in terms of operational performance that arise, if deterioration is not addressed. In selecting a life cycle management approach for an asset-class or sub-class, an agency must understand asset deterioration, performance, and risk over time and determine what decisions need to be made throughout the asset’s service life to ensure that the asset is managed effectively. In turn, the management strategies affect the supporting data that must be collected and analyzed.

There are many different criteria that can be used to manage assets and establish life cycle strategies. Performance can be measured in many ways, but with transportation infrastructure, asset condition is typically used either as the measure of performance, or as the measure of an asset’s ability to provide the desired function, for example, carry the designed traffic capacity safely under design conditions. Additional information on performance management and performance criteria is provided in Chapter 6.

Depending on the criteria for performance, the available performance data, and the risk of asset failure, agencies will typically choose a standard approach to establishing a life cycle strategy for a given class or subclass of assets. Life cycle strategies describe the types of actions to be applied to an asset throughout its service life, including activities such as maintenance, preservation, and rehabilitation. This section describes how life cycle management is applied to transportation infrastructure assets to assist in selecting an effective approach for any class of assets.

Common Approaches to Managing Transportation Assets

All infrastructure assets are designed to have a certain functional service life. However, there are major differences in how assets deteriorate (physically or in performance), the available treatment options to address deterioration, and different levels of consequence in terms of operational performance that arise, if deterioration is not addressed. In selecting a life cycle management approach for an asset-class or sub-class, an agency must understand asset deterioration, performance, and risk over time and determine what decisions need to be made throughout the asset’s service life to ensure that the asset is managed effectively. In turn, the management strategies affect the supporting data that must be collected and analyzed.

There are many different criteria that can be used to manage assets and establish life cycle strategies. Performance can be measured in many ways, but with transportation infrastructure, asset condition is typically used either as the measure of performance, or as the measure of an asset’s ability to provide the desired function, for example, carry the designed traffic capacity safely under design conditions. Additional information on performance management and performance criteria is provided in Chapter 6.

Depending on the criteria for performance, the available performance data, and the risk of asset failure, agencies will typically choose a standard approach to establishing a life cycle strategy for a given class or subclass of assets. Life cycle strategies describe the types of actions to be applied to an asset throughout its service life, including activities such as maintenance, preservation, and rehabilitation. This section describes how life cycle management is applied to transportation infrastructure assets to assist in selecting an effective approach for any class of assets.

- Chapters

-

Chapter 4

Sections - Chapter 4 Home Page

- Chapter PDF

Chapter 4

Quick Links

4.2.1

Life Cycle Management Approaches

Different types of assets require different management approaches to operate effectively and provide the expected level of service.This section introduces common management approaches used by transportation agencies to appropriately manage asset service life at both a network and asset level.

TAM Webinar #32 - Life Cycle Planning and Management

Virtually all transportation infrastructure assets are designed to have long service lives, lasting years or even decades. This means life cycle management must include long-term predictions that come with inherent uncertainty. Further complicating matters, the condition or performance of some assets may be difficult, expensive, or impossible to discern. This is most common with geotechnical assets or hidden elements on complex structures. Addressing this uncertainty requires integration with the agency’s risk management practices, and consultation with technical experts, such as hydraulics and geotechnical engineers. Risk management practices are discussed in more detail in Chapter 5. This section highlights how uncertainty should be considered when selecting a management strategy to maximize service life and address risk.

Condition-Based Management

A condition-based management approach is the life cycle management approach that is the most commonly associated with asset management at U.S. transportation agencies. In condition-based management the condition of an asset is measured, and used to forecast and identify the onset of failure. Maintenance and preservation activities are identified to address the failure and restore or extend service life. While the objective of asset management is to support the reliable performance of the asset, the performance measures most commonly used for physical assets are condition-based. Agencies that are very advanced in their asset management practices may be able to apply the condition-based management approach to other aspects of asset performance.

Condition-based management relies on the collection and analysis of asset condition and defect data. This data is then used to understand the current state of individual assets and when aggregated is used to predict the future condition state of similar asset types. When linked with intervention data and condition threshold information, the future impact of potential actions can be assessed, all with the view of optimizing an asset’s service life cost-effectively. Accordingly, a condition-based management approach combines condition monitoring with performance predictions and knowledge of preventive or restorative actions, to establish a cost-effective life cycle plan. The condition-based management approach can be applied to simple and complex assets, groups of single assets or a whole network. In a network perspective, components could be individual assets such as pavement segments and bridges and at a project level, components could be elements of individual assets.

Indiana DOT

Overhead sign structures are critical to safe and effective highway performance since they support signs, cameras, sensors and other equipment in support of routine and emergency operations. These structures typically have long service lives, but failure risk exists if they are not maintained. Indiana DOT found that failure to their overhead sign structures could be effectively mitigated through routine, real time condition monitoring and condition forecasting for predicting failure. Therefore, the Indiana DOT uses a condition-based approach for maintaining its overhead sign structures.

Indiana DOT’s condition-based maintenance approach involves the steps listed below to ensure the overhead sign is installed corrected, material specifications are met, and the connection to the ground is secure:

- Professional engineers perform inspections

- An asset inspection report is developed

- The asset inspection reports are submitted to the districts

- The districts review the reports and prioritize work activities

- Work orders are developed to address the highest-priority needs

- In-house crews or local contractors perform the work

As a result of the DOT’s condition-based maintenance approach, the department realized an increase in the amount of collaboration between districts and an improvement in how overhead sign structure repairs and replacements are monitored and prioritized.

Source: FHWA (2019). Handbook for Including Ancillary Asses in Transportation Asset Management Programs (pending publication in 2019).

Interval-Based Management (Age Based)

Interval-based Management is most commonly applied to operations assets (striping, signs, guardrail), where just an inventory is maintained. Condition assessments may not be financially feasible or practical. Additionally, these assets are often related to compliance, meaning their condition state either meets a specific standard, or does not. With interval-based management, asset performance data or manufacturer’s suggested life estimates are used to establish a time interval representative of the service life beyond which the cost of asset failure outweighs the cost of replacement. The service life being the average life that all assets or components of a type are expected to last. Cyclically applied interventions can also be classed as interval-based management strategies, as there is fixed period between a set of predefined actions that have to be taken. An interval-based approach is most commonly applied to manufactured assets with highly uniform performance levels. It is less applicable to assets constructed on site or long-lived complex assets where there is a greater level of uncertainty surrounding the expected life of the asset. Examples of the types of assets that are often maintained on an interval-based approach are signals, ITS equipment, and other mechanical and electrical related items.

Reactive Management

Reactive management unlike condition or interval maintenance does not use forecasting to understand the likely timing of an intervention. Accordingly, reactive management excludes all or most actions to address asset condition or performance, until the asset reaches an unacceptable condition state. The condition state may be influenced by accumulated deterioration or a specific event, like a crash or intense storm. Reactive-management is commonly applied to low-value or less critical assets, redundant assets, or assets for which failure represents an acceptable risk. To create a reactive-based management strategy, minimum acceptable condition thresholds, must be defined. Reactive management strategies often require an agency to have a mechanism to deliver required work within a specified time frame, to avoid unacceptable levels of risk. This may include properly staffed and equipped in-house maintenance forces or “stand-by” contracts, so work can be dispatched and delivered quickly. Examples of assets managed using a reactive-based approach include fences, brush, lighting, raised pavement markers, impact attenuators, and rockfall.

- Chapters

-

Chapter 4

Sections - Chapter 4 Home Page

- Chapter PDF

Chapter 4

Quick Links

4.2.2

Selecting the Right Management Approach

The selection of a management approach considers the mechanisms that lead assets to fail to provide their required or desired service, the consequences of failure, available intervention options and related costs.

Factors for Comparing Life Cycle Management Approaches

Failing to achieve a service level target requires an intervention, or reassessment of the reasonableness of the target. If improvement is required, selecting a management strategy is a function of where performance is insufficient. Safety improvements can reduce crash rates, additional lane capacity can improve travel time reliability, operational enhancements can improve emergency response rates and road availability during inclement weather. Where condition is below target, at a network or corridor level, interventions may be required in multiple areas.

Selecting interventions to achieve condition targets for an asset class or subclass is a data-driven, risk-based process. It evaluates what circumstances lead to asset failure, the subsequent consequences of failure, the options available to avoid failure and their costs. Costs should include the cost to monitor/analyze/ manage an asset in addition to the cost to repair. Based on an understanding of these factors, an agency can determine what strategy will be the most appropriate. The three management strategies introduced in the previous section are incorporated into Table 4.2 along with summaries of the various factors used to compare the approaches.

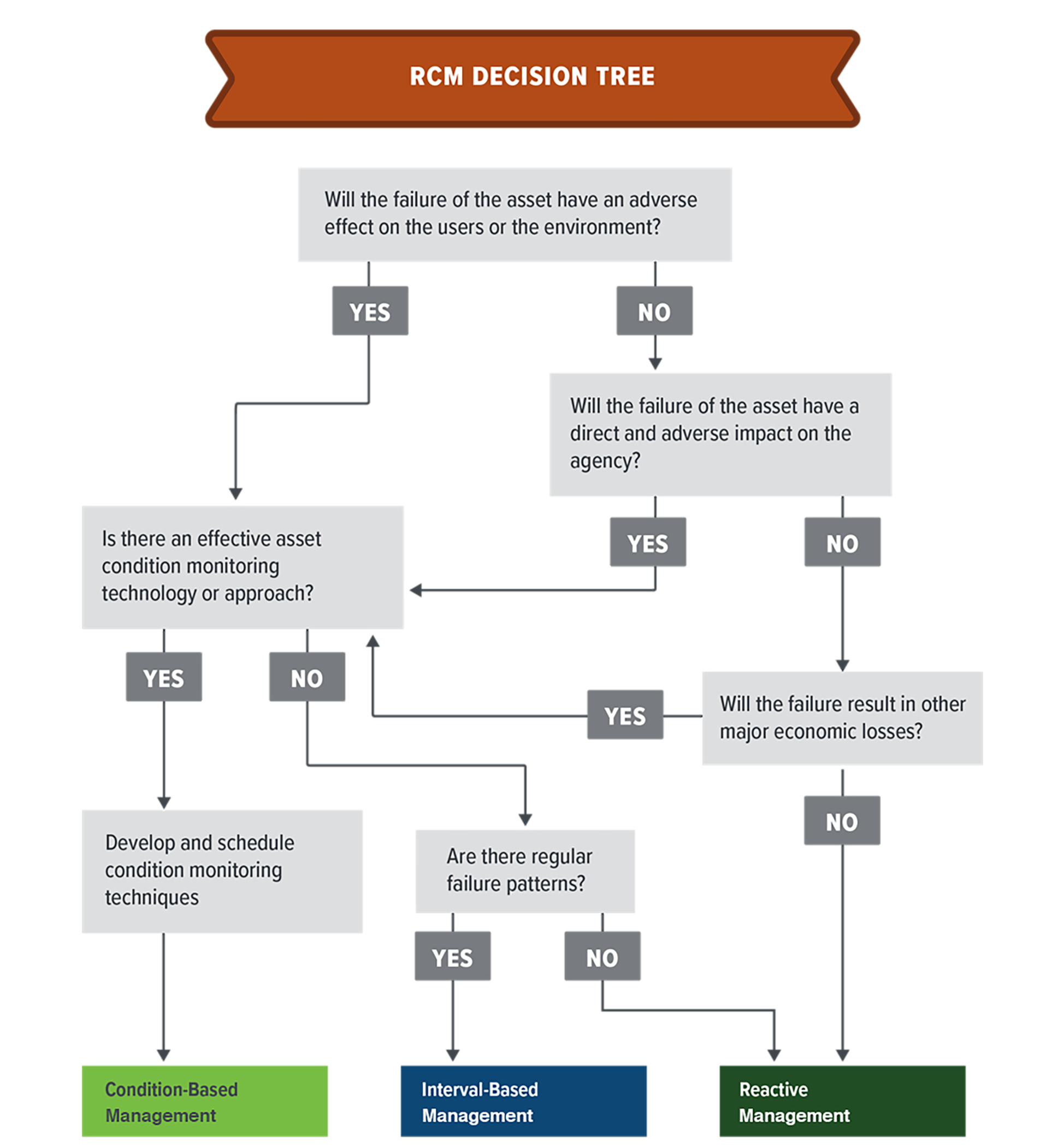

Reliability Centered Maintenance

Several of the principles described in this section are based on a Reliability Centered Maintenance (RCM) approach, a technique that is sometimes used by an agency to identify the most appropriate management method. Looking at an asset or asset class from an RCM perspective helps to select a management approach based on safety, operational and economic criteria. RCM is commonly applied to complicated assets that may require a range of management approaches for different components of the asset.

Table 4.2 - Comparison of Management Strategy Approaches.

Adapted from SAE International 2009

| Management Approach | Condition-Based | Interval-Based | Reactive-Based |

|---|---|---|---|

| Decision Making (intervention) Approach | Selects intervention based on a forecasted condition exceedance interval. | Asset is treated based on a time or usage basis whether it needs it or not. | Treatment is performed to fix a problem after it has occurred. |

| Data Needs | Inventory information (Asset / Component) Historical condition and expert data – deterioration curves Current condition and defect data Historical Intervention and cost data – intervention strategies. Asset / component type and material data Intervention thresholds for condition | Inventory information (Asset / Component) Asset / component age Remaining useful life of asset / component Timing and type of last action Interrelationships of different interventions, and how they affect the selection and timing of downstream actions | Inventory information (Asset / Component) Current Condition data Intervention thresholds for condition Historical cost data |

| Life Cycle Planning Expectations | Require the ability to understand the effects of different funding strategies. Wish to forecast the future condition state of the network or specific asset classes. Wish to minimize the life cycle cost. | Wish to gain an understanding of the typical average cost to manage the network or specific asset classes | General costs estimates based on experience. Limited need to actively manage the asset. |

| Considerations | Cost of collecting and analyzing condition information and developing forecasting models. | Diminished cost effectiveness / efficiency compared to condition modeling. Does not support knowledge development of asset behavior (inhibiting the move to more cost-effective regimes). | Often considered immature but is appropriate for assets if only minor consequences occur from a service disruption. |

| Typical Usage Cases | High risk / criticality assets or risk must be more actively managed. Large portfolios or high value assets of similar construction forms Scenario planning is required Long-lived assets that can have numerous management approaches applied to them. More advanced asset management planning is required Cost uncertainty over time must be assessed (stochastic modeling) | Moderate or low risk assets. Mandated manufactures management regimes or Short-lived assets Buried assets where condition data is hard to obtain. Assets where the cost to collect condition data is expensive relative to the maintenance activity that is required | Low risk or criticality assets. Assets where the effects of accumulated defects are not critical to their functionality. Assets that are likely to be subject to unforeseen events or impairment e.g. barriers or light poles. |

The RCM process has its roots in the aviation industry related to the mechanical components of aircrafts, but has been adopted across multiple industries for mechanical, electrical and infrastructure assets. Within the highways industry RCM has been considered for ITS assets. More information on the use of RCM for ITS assets has been published by Austroads (2016): Reliability-centered Maintenance Strategy and Framework for Management of Intelligent Transport System Assets.

RCM considers seven fundamental questions to select the most appropriate management approach for a set or type of assets (SAE International 2009). These questions can be applied to the selection of life cycle management approach. Based on the responses to these questions, an agency can determine what maintenance approach, for which parts of the asset, will maximize the likelihood of an asset performing its desired function for the lowest practicable cost. These questions are as follows:

- What is the item supposed to do and what are its associated performance standards?

- In what way can the asset fail to provide the required functions?

- What are the events that cause each failure?

- What happens when each failure occurs?

- In what way does each failure matter?

- What systematic task can be performed proactively to prevent or diminish to a satisfactory degree the consequences of the failure?

- What must be done if a suitable preventive task cannot be found?

RCM can be presented in a decision tree to aid agencies in selecting the best management approach. Agencies can also customize the questions and decision tree to meet their specific need. Figure 4.6 represents a portion of a decision tree customized to select the appropriate management approach for ancillary highway assets. By applying these questions to an asset class, an agency can prioritize asset classes for monitoring and active management. An agency can also determine which assets present limited risks to system performance and can be managed through less expensive means.

Figure 4.6 Maintenance Approach Decision Tree

Source: FHWA. Expected 2019. Prioritizing Assets for Inclusion in Transportation Asset Management (TAM) Programs.

Indiana DOT

Overhead sign structures are critical to safe and effective highway performance since they support signs, cameras, sensors and other equipment in support of routine and emergency operations. These structures typically have long service lives, but failure risk exists if they are not maintained. Indiana DOT found that failure to their overhead sign structures could be effectively mitigated through routine, real time condition monitoring and condition forecasting for predicting failure. Therefore, the Indiana DOT uses a condition-based approach for maintaining its overhead sign structures.

Indiana DOT’s condition-based maintenance approach involves the steps listed below to ensure the overhead sign is installed corrected, material specifications are met, and the connection to the ground is secure:

- Professional engineers perform inspections

- An asset inspection report is developed

- The asset inspection reports are submitted to the districts

- The districts review the reports and prioritize work activities

- Work orders are developed to address the highest-priority needs

- In-house crews or local contractors perform the work

As a result of the DOT’s condition-based maintenance approach, the department realized an increase in the amount of collaboration between districts and an improvement in how overhead sign structure repairs and replacements are monitored and prioritized.

Source: FHWA (2019). Handbook for Including Ancillary Asses in Transportation Asset Management Programs (pending publication in 2019).