- Chapters

-

Chapter 4

Sections - Chapter 4 Home Page

- Chapter PDF

Chapter 4

Quick Links

4.1.3

Developing Life Cycle Strategies

Most transportation infrastructure assets have long service lives, lasting years or decades. Making decisions based on short-term performance without an understanding of the long-term cost effectiveness usually leads to higher future costs. Through life cycle management, agencies can develop strategies for maximizing their ability to meet both short- and long-term goals with available resources.

TAM Guide Book Club #3: Life Cycle Planning and Management

Adopting life cycle management can often achieve desired performance levels at lower life cycle costs than traditional strategies. Improved performance comes from analyzing the impact of various sequences of treatments on the future performance and costs of an asset class or subclass. By comparing the costs and benefits of long-term sequences of treatments, agencies can develop life-cycle strategies which provide the best practical long-term performance at lowest practical long-term costs. The implementation of life cycle strategies also enables an agency to better address its stewardship responsibilities and improve the alignment between agency investments and priorities.

By establishing sound long-term strategies, agencies can minimize the life cycle costs of preserving assets, while also managing asset performance to a defined target, the extent practicable with available resources. While strategies with a short-term outlook may provide better short-term performance, they can greatly increase the risk of higher future costs.

Whole-Life Approach to Asset Management

U.S. DOT

When developing long-term strategies, it is important to differentiate between the primary asset, with a long service life, and elements or components of that asset, that may be repaired or replaced to allow the primary asset to achieve its design life. In the case of pavements, the pavement structure may require several wearing surface replacements, either through overlay or removal and replacement of the wearing surface, to ensure the pavement structure lasts as long as intended. For assets such as bridges or signal installations structural elements or functional components may be repaired or replaced multiple times within the service life of the primary asset. In almost every case the failure to perform these maintenance and preservation actions, or failure to perform them at the appropriate time will lead to reduced service life of the primary asset.

When determining the appropriate treatment for a long-life asset, it is important to understand the root cause of the condition being prevented or corrected. Inexpensive treatments that address the visible or measured condition without addressing the cause of the distress are not cost effective. Examples of such treatments include:

- Thin overlays of asphalt pavements that are displaying structural cracking.

- Painting corroded structural steel members without proper surface preparation.

- Filling leaking bridge joints without proper materials or preparation.

While such treatments may, in some specific circumstances, be needed to provide minimal function or safety until a more substantial repair can be made, they should not be considered part of an optimal life cycle strategy.

Treatments made to achieve or extend the service life of these assets can also address changes in conditions or assumptions that have occurred since the asset was designed and constructed. Examples of these types of treatments include seismic retrofitting or applying scour protection to bridges, or increasing the hydraulic capacity of corrugated culverts by relining with smooth interiors. Each of these treatments reduces the risk of premature failure to an extreme event, and may at the same time address other structural or functional needs, without replacing the primary asset or changing its functional nature, i.e. increasing traffic-carrying capacity.

Life Cycle Strategies in Construction and Design Stages

Transportation infrastructure assets are expected to provide agencies with a desired level of performance over their design lives. To ensure the desired performance is achieved, decision-makers should consider factors that impact asset service life and future costs at the time of construction. This is commonly performed as part of the project development process to select a preferred design alternative. Factors to forecast should include design criteria, constraints, standards, and risks.

- Traffic

- Environmental and climatic conditions

- Material properties

- Design standards

- Operational constraints

- Construction practices

- Climate change

- Changing customer expectations

- Regional, state and national travel pattern changes

- Advancing technology

Because these factors contribute to asset performance, deterioration and the continued functionality of the asset, they must be considered when developing life cycle strategies in early and later stages of asset life. Life cycle strategies are based on an understanding of how these factors contribute to the rates of deterioration, how well the asset will accommodate future requirements and which treatments are effective in addressing deterioration or slowing the rate at which the asset deteriorates or underperforms.

Operation, Maintenance, and Rehabilitation Strategies

Treatment strategies consider how the asset, once constructed, will be managed to ensure it attains its design life, while maintaining the desired level of functionality. Special consideration should be given to long-life assets. There are three primary reasons short-term strategies are inefficient for long-life assets:

- As long-life assets age, deterioration accelerates, and there is greater risk of performance failing to meet current needs.

- As deterioration increases, the cost of treatments addressing deterioration tend to increase exponentially.

- Inexpensive treatments that restore condition but do not address the root cause of the deterioration will fail prematurely, leading to higher future costs.

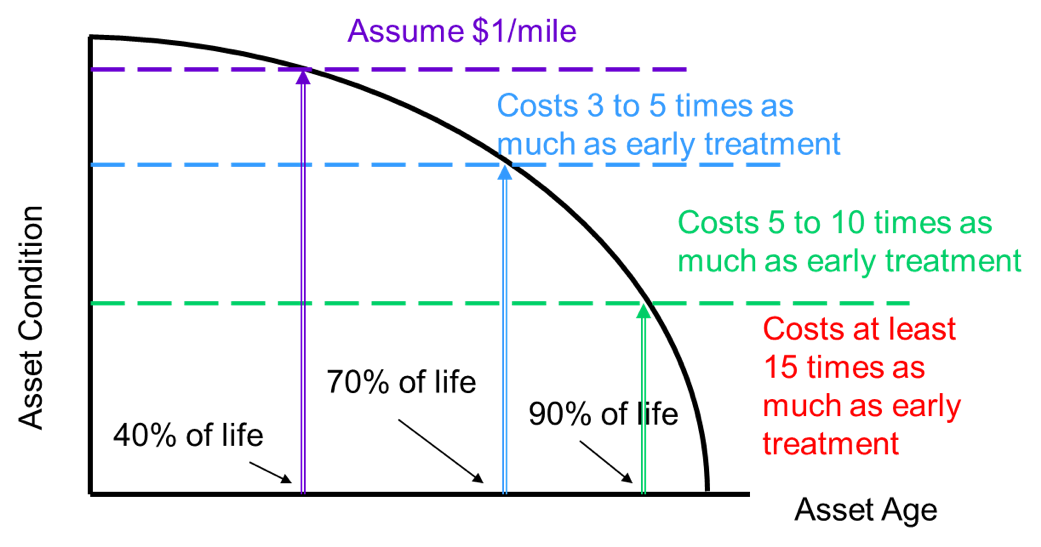

These factors are reflected in Figure 4.4, which illustrates these concepts using a generic asset deterioration model. As shown in the figure, the average cost of treatment increases substantially as assets age. Additionally, the rate of deterioration tends to accelerate as assets age. Long-term strategies that use low-cost treatments early in an asset’s life cycle tend to improve asset condition very cost-effectively by deferring the need for most costly repairs.

Figure 4.4 Example Showing the Cost of Deferred Treatments

Source: Applied Pavement Technology, Inc. 2018

South Dakota DOT

To analyze the benefits of potential actions at the network level, South Dakota DOT (SDDOT) uses incremental benefit cost (IBC) analysis and deterioration models to determine the combination of feasible reconstruction, rehabilitation, and preventative maintenance treatments and timing at the network level that will give the best overall pavement and bridge conditions at the lowest practicable life cycle cost.

IBC analysis is used to answer a series of two important questions regarding pavement section treatments: Should the section be improved now, and if so, what is the best improvement to make? SDDOT’s IBC analysis process answers this set of questions by determining the combination of feasible reconstruction, rehabilitation and preventative maintenance treatments and timings that will use the anticipated state funds to yield the optimal overall asset conditions on the state highway network over a 20-year analysis period and the best long-term value to the system users (SDDOT TAMP, 2018).

Source: http://www.sddot.com/resources/reports/SDDOT2018TAMPFHWASubmittal.pdf

Considering Transformational Changes in Life Cycle Management

Life cycle management requires an understanding of past performance to predict future performance and plan appropriate actions. However, as technology advances and society’s needs change, the inputs and objectives of life cycle management need to adapt. Technology can lead to new materials or techniques that allow agencies to get longer life from existing assets. However, technology can also lead to broader societal changes that may make the need for some assets obsolete. Similarly changes in standards and regulations, may make it necessary to replace or update some assets prior to the planned ends of their service lives. Asset managers should regularly review their assumptions about anticipated asset service lives, consider new treatment options, and adjust to technological and regulatory trends and adjust the life cycle approach accordingly. Much of the information to support this effort can be found in agency’s long-term planning documents, as discussed in Chapter 2.

TAM Webinar #49 - Improving Your Next TAMP Miniseries: Improving Life Cycle Planning and Management

Incorporating Resilience in Life Cycle Strategies

Environmental changes such as extreme weather, temperature rise, sea level change, and changes in other environmental conditions can threaten transportation infrastructure. Even when these changes don’t increase the risk of failure, they can require infrastructure owners to change their strategies for managing assets. This is particularly important for long-life infrastructure assets such as bridges, pavement, culverts, and geotechnical assets.

Resilience is the term used to describe an asset’s ability to withstand environmental changes. Resilience can be considered at all stages of an asset’s life and should be an integral aspect of any life-cycle strategy.

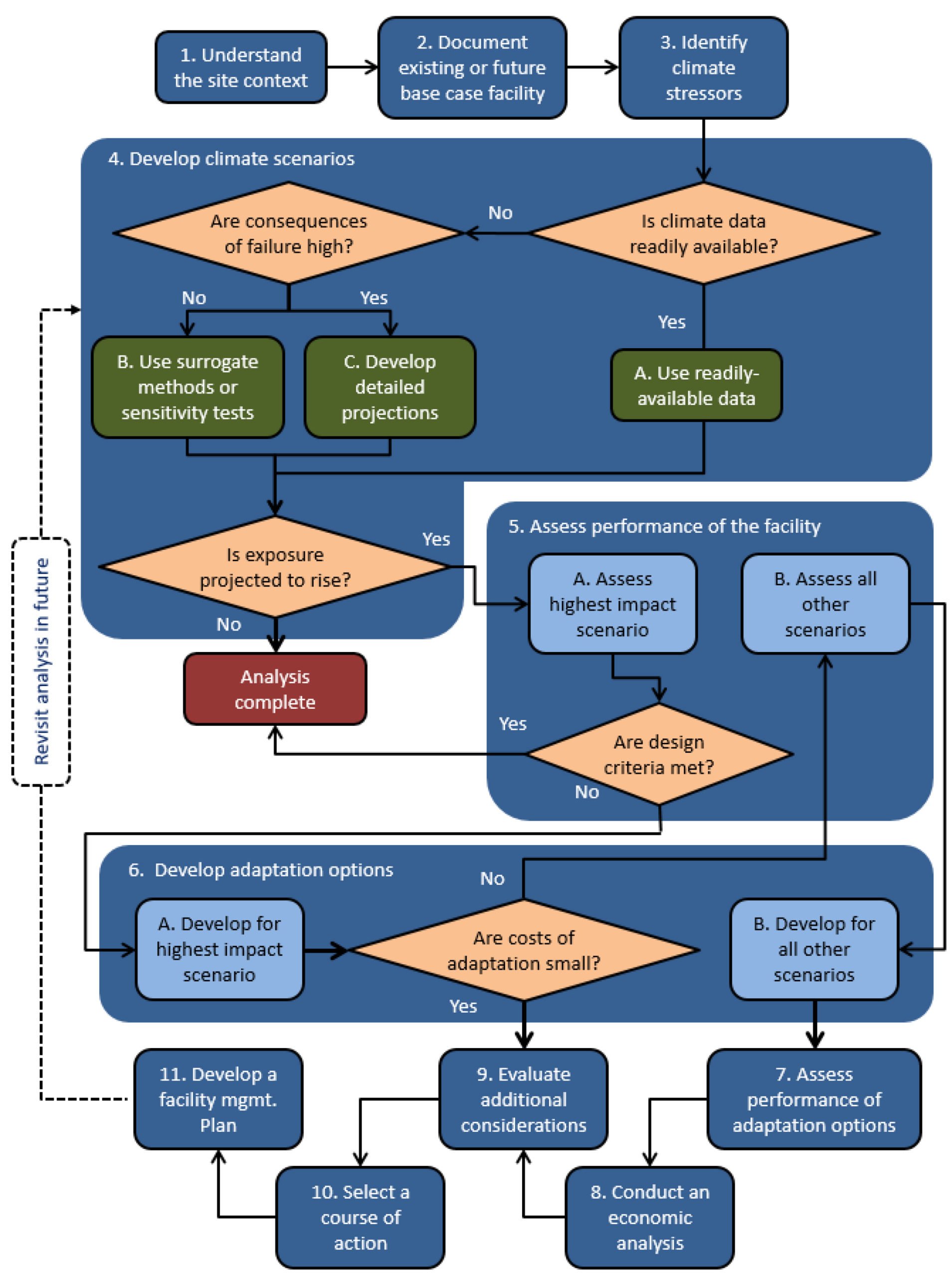

FHWA developed the Adaptation Decision-Making Assessment Process (ADAP) as a tool for planners and designers to address resilience in the design of infrastructure projects. While ADAP was developed to be used on a project-by-project basis, it can also be applied to the development of a lifecycle strategy. Figure 4.5 shows the 11 step ADAP process. The key difference between applying the ADAP process to developing a life-cycle strategy, as compared to a project, is in step 1. Understand the site context. When applied to a project this step is focused on a specific physical location, bounded by the project limits. When applied to developing a life-cycle strategy, the site context will likely be broader to an area that is expected to be subject to a given environmental change, such as increasing seasonal temperatures, or sea level rise. Once the proper context is established, the process steps can be followed to evaluate potential strategic adjustments that will allow life cycle management practices to account for the anticipated effects of the environmental change.

Figure 4.5 Decision Tree of the ADAP Steps

Source: FHWA. 2016. TEACR Engineering Assessment. Adaptation Decision-Making Assessment Process (ADAP). FHWA-HEP-17-004

New York State DOT

In 1994, New York State DOT (NYSDOT) determined that it needed to modernize its bridge designs to have longer service lives to help reduce future rehabilitation and replacement costs. Prior to this effort, the agency designed bridge decks to for a 50-year service life with a planned rehabilitation at year 35. The goal for this effort was to double the bridge deck design life to 100 years with a planned rehabilitation at year 75. The NYSDOT Materials Bureau investigated the major causes of bridge deck deterioration and determined that the primary cause of failure was corrosion of the reinforcing steel due the intrusion of chlorides from winter maintenance activities. Upon further investigation, it was determined that the chlorides were penetrating the bridge decks both through cracks and the natural porosity of the concrete. As a result of this research, the agency began a research and development effort to design a new standard concrete mix design that had lower permeability, higher resistance to cracking, and was pumpable to support standard bridge deck construction practices.

The result of the Materials Bureau’s effort became NYSDOT’s “Class HP” concrete, which utilizes fly ash (a byproduct of electric power production) and micro silica (a byproduct of electric arc furnaces used in manufacturing) to replace some of the Portland cement in its standard bridge deck concrete. These new materials are finer in size than cement particles, resulting in well graded denser packing of particles in the concrete, which reduces permeability. Class HP also creates less heat while it cures (or hardens), which reduces the occurrence of thermal shrinkage cracks when the deck cools. In 1997, Class HP became NYSDOT’s standard concrete mix for bridge decks. By using a failure mode analysis to identify the primary causes for bridge deck deterioration, NYSDOT could use new materials technology to address those causes and significantly lengthen the design life of its bridge decks.

Maine DOT

Maine is a cold-weather state with soils that are susceptible to severe frost conditions during winter months. In cooperation with FWHA and its Transportation Engineering Approaches to Climate Resiliency (TEACR) effort, Maine DOT undertook a project to assess the impacts of changing climate on the performance of pavements and develop strategies to offset those changes. The study looked at anticipated changes in both temperature and precipitation over the course of the 21st century. The study followed the ADAP process as shown in figure 4.6. The study indicated that anticipated climatic changes will lead to moderate changes in pavement performance. The study identified both engineering and operational adjustments Maine DOT can adopt to address these changes. The full report can be found on FHWA’s website at: https://www.fhwa.dot.gov/environment/sustainability/resilience/ongoing_and_current_research/teacr/me_freeze_thaw/