- Chapters

-

Chapter 4

Sections - Chapter 4 Home Page

- Chapter PDF

Chapter 4

Quick Links

4.1.1

Defining Life Cycle Management

Through life cycle management, agencies employ data on asset condition, treatment options, costs, deterioration rates, replacement cycles, and other factors to determine the most cost-effective, long-term strategies for managing assets throughout their lives.

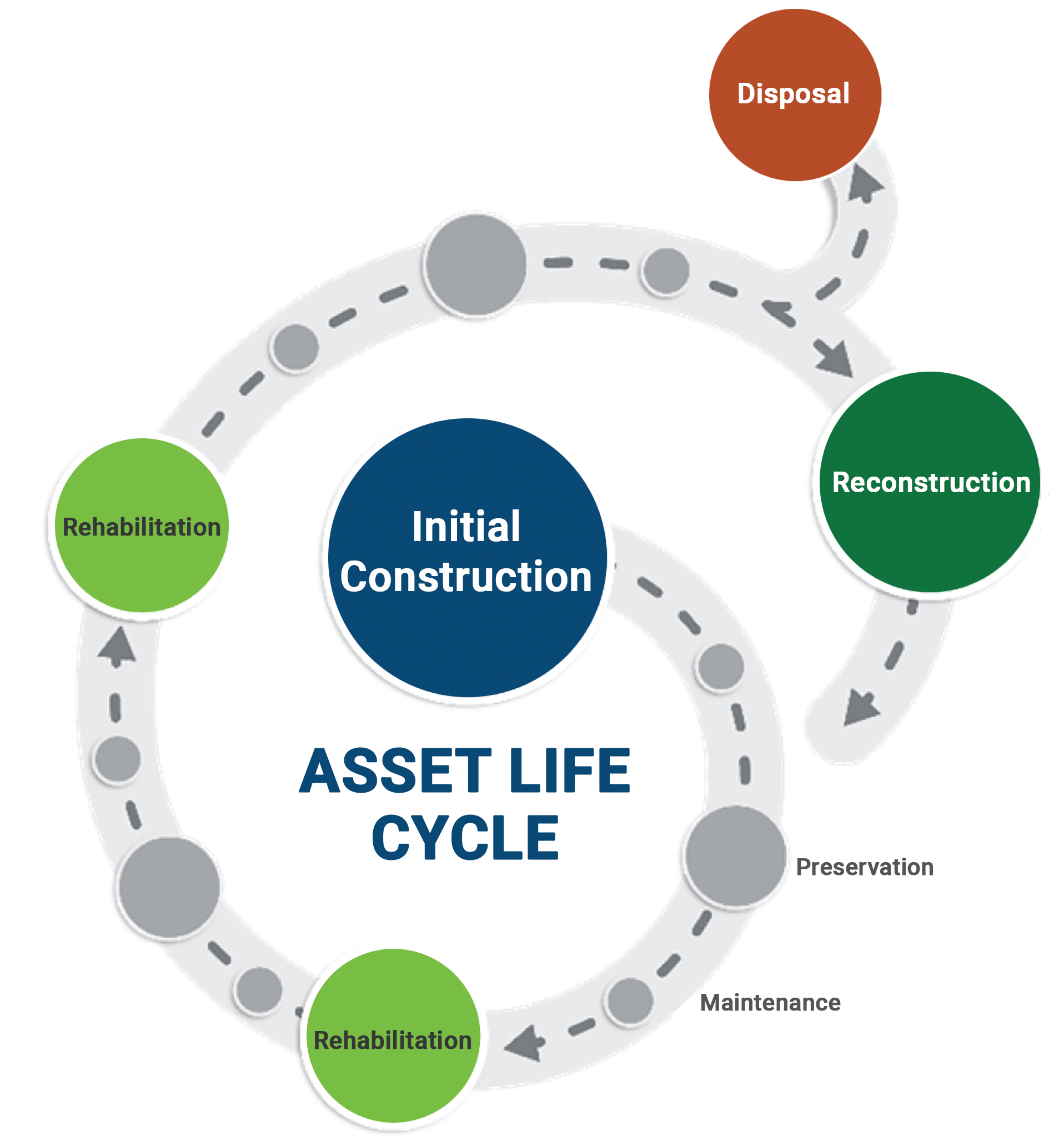

All transportation infrastructure assets have a life cycle, which includes several stages from initial construction to removal or replacement (see figure 4.1). Life cycle management is an investment approach that considers maintenance, renewal, replacement, or repair options through an asset’s service life with the intent to maximize the benefit provided by the asset at the minimum practicable cost. It employs data on asset condition, treatment options, costs, deterioration rates, replacement cycles, and other factors to evaluate trade-offs between possible investment strategies and treatment timings. Effective life cycle management requires knowledge of the agency’s strategic priorities and an understanding of the performance criteria driving investment decisions, so the right management strategy can be identified and implemented for each asset class. Aligning asset management measures with agency priorities ensures the investments made to extend asset service life provide the maximum impact to the agency’s long-term goals.

Figure 4.1 illustrates a variety of interventions that occur over an asset life cycle. The larger circles represented in the figure are service life altering, and represent a capital investment in infrastructure. Capital investments provide significant life extension, and may alter or enhance the operational nature of the asset, e.g. expand capacity, without fully replacing the asset. Maintenance (reactive, interval based and routine) activities are required throughout the life cycle to ensure the asset achieves its service life.Preservation treatments restore condition or performance to achieve service life, and may extend service life as well, but do not significantly alter the operational nature of the asset. Some agencies may capitalize investment in these preservation activities; however, regardless of the timing and character of the selected interventions, all of them are part of the life cycle management process. More (lower cost) maintenance interventions can offset the number and cost of the larger (and more costly) interventions. Balancing the right intervention, at the right time, can greatly reduce the overall investment needed for infrastructure to be reliably available for providing service.

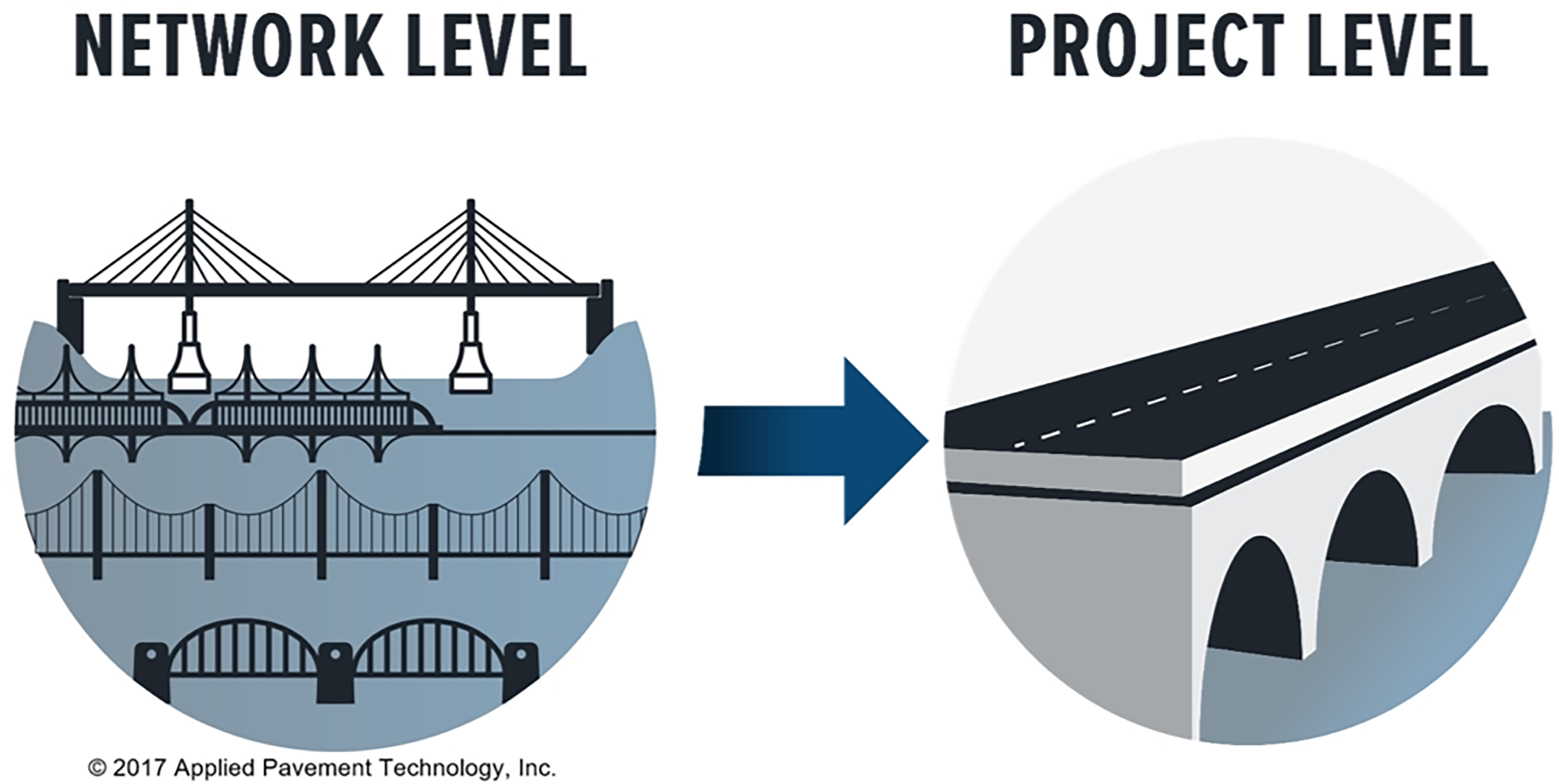

Life cycle management can be used at both network level and at project level. At network-level, life cycle management considers the needs of an entire asset class, as well as the available funding, to determine the most appropriate life-cycle strategies. For example, analysis can establish the optimal proportions of overall investment that should be allocated to different types of interventions over the network, to minimize investment to achieve performance targets or an average condition level. At a project level, life cycle management is commonly used to develop asset-specific strategies. Project level life cycle plans provide input into the network level life cycle plans. Large bridges or other distinct network components are often planned and managed in this manner.

Life Cycle Cost Analysis (LCCA) is an engineering-economics approach that can be used to quantify the differential costs of alternative design approaches. Network level life cycle management, while a more wholistic process that manages every stage of an asset’s life, may employ LCCA or other forms of analysis to inform management decision-making. Figure 4.2 highlights some of the major differences between life cycle management and life cycle cost analysis. At the network level, LCCA can be used to understand how to best manage the network as it ages. At a project level, it is used to understand what are the most effective actions to be taken on the assets within the project scope at the time of project delivery. Both network level and project level analyses contain many aspects of engineering economic analysis, such as consideration of user benefits, user costs, and the time-value of money to identify alternatives that represent the lowest practicable life cycle cost over the analysis period to achieve the desired objectives.

Figure 4.2 Attributes of network level life cycle management and project level life cycle cost analysis

- High level.

- One asset class or subclass.

- Multiple locations.

- Looks at impacts of varied treatment timing.

- Considers future cost changes.

- Detailed.

- Multiple asset classes.

- Single location.

- Treatment timing fixed for all options.

- Uses discount rate.

Source: Applied Pavement Technology, Inc. 2017

Decision Making Context

Life cycle management is driven by the need for owners to provide consistent service to those that use the transportation system with the resources available. Infrastructure decision making can take place at several levels within an organization, and in each case, considers different but often interrelated factors. These are illustrated in table 4.1.

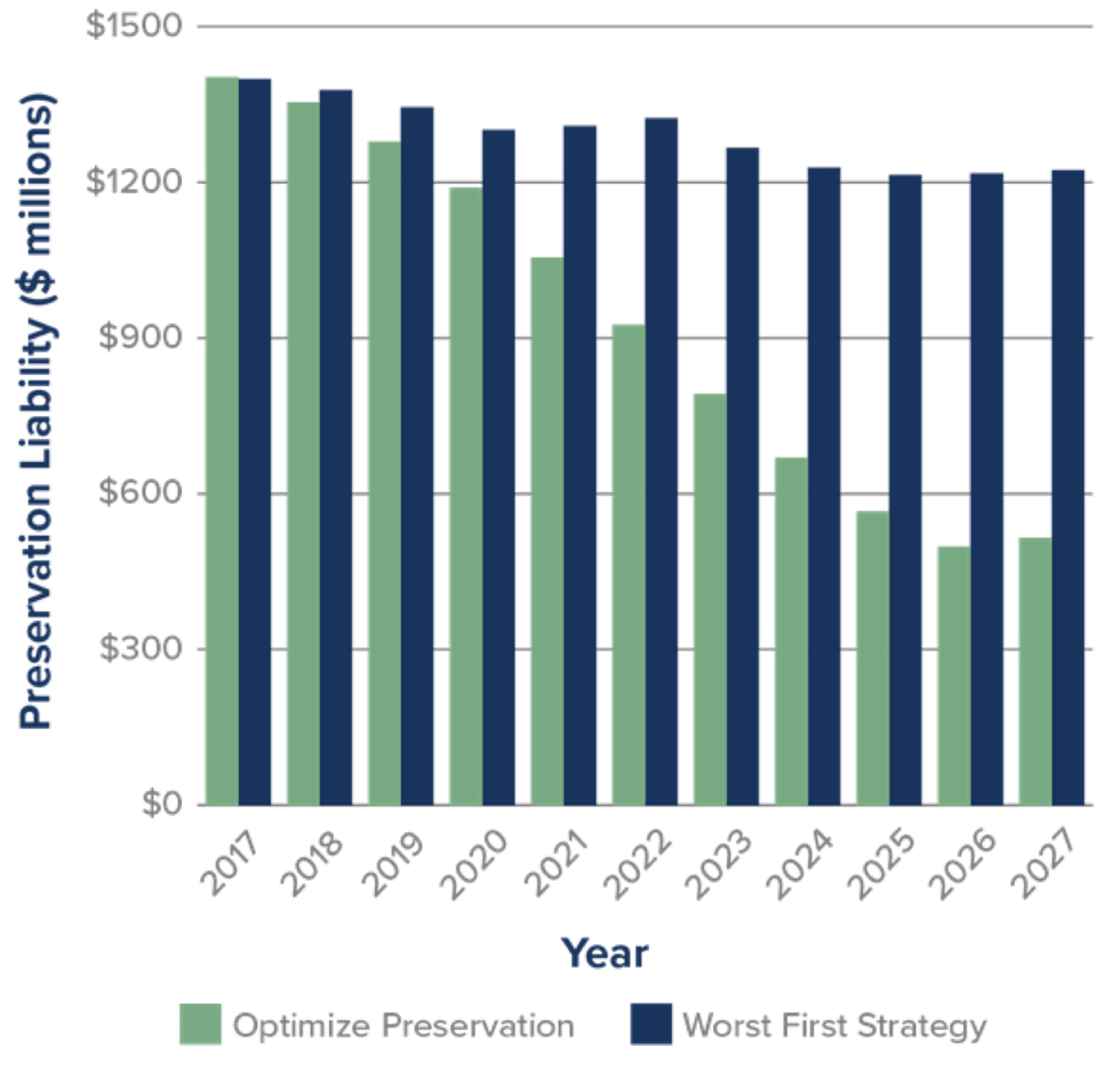

Figure 4.3 Analysis of KYTC Future Costs Under Two Strategies

Source: Kentucky Transportation Cabinet Transportation Asset Management Plan, 2018.

Table 4.1 - TAM Decision-Making Contexts

Key Questions and Connections to Other Chapters

| Strategic | Tactical | Operational | |

|---|---|---|---|

| Key Decisions | Setting goals and objectives. | Capital investment prioritization and scoping and Integration of maintenance and renewal strategies | Delivery of the capital program, routine maintenance, and highway-operations activities. |

| Decision Makers |

| Directors and managers who are asset stewards. | District and field mangers, supervisors, and staff. |

| Key Questions |

|

|

|

| Other Factors | Decisions and outcomes of these strategic questions help focus investment. They add value to overall performance of the transportation system by setting priorities, values, and help prioritization of investment at lower levels. Creating new assets and disposing of existing ones are strongly influenced by decisions and priorities defined at this level. Chapter 2 discusses these considerations in more detail, and the level of service section in this chapter discusses linking these strategic priorities to decision-making at lower levels. Performance and target setting in Chapter 6 also discusses this linkage and how targets can be set to achieve these strategic goals. | This Chapter focuses on these questions and on the analysis that informs their corresponding answers and decisions. Life cycle management and analysis focuses on the existing transportation system and evaluates how:

| Delivering a program work, ranging from maintenance activities to capital improvements, requires a coordinated management of a large workforce. It requires processes that minimize input of resources to get the output required for desired system performance. Work management systems, efficiency and improvement techniques and performance management focus on improving decisions at this level. These concepts are discussed in Chapter 5, 6 and 7. |

Kentucky Transportation Cabinet (KYTC)

In the early 2000s, KYTC found that the cost of hot-mix asphalt (HMA) was increasing faster than its budget to maintain pavement conditions. In response, KYTC evaluated the feasibility of strategies that relied heavily on preventive maintenance overlays such as thin HMA overlays (< 1 inch), chip seals, cape seals, and slurry seals. KYTC found that while the costs of these treatments were substantially less than a traditional HMA overlay, their service lives were only marginally shorter. As a result, the agency began increasing the use of these treatments on its secondary system. As part of developing its risk-based TAMP in 2018, KYTC evaluated life cycle strategies, as shown in Figure 4.3 Analysis of KYTC Future Costs Under Two Strategies that expanded the use of preventive maintenance overlays to its parkway and interstate pavements. The analysis results led the agency to select a life cycle management strategy that maximizes the use of preventive maintenance overlays on secondary roads and parkways and increases their use on interstate pavements over time. As shown in Figure 4.3, this new life cycle strategy achieved conditions over the 10-year TAMP analysis period that would have cost an additional $644 million if they had continued to rely on traditional 1- to 2-inch HMA overlays. By implementing these improved strategies, KYTC has significantly reduced the risk that the infrastructure will reach an unsustainable cost to maintain in the future.

Source: KYTC Transportation Asset Management Plan, 2018. http://www.tamptemplate.org/wp-content/uploads/tamps/048_kentuckytc.pdf