- Chapters

-

Chapter 3

Sections - Chapter 3 Home Page

- Chapter PDF

Chapter 3

Quick Links

3.3.2

Understanding the Organization

Transportation agencies must implement changes when adopting new asset management practices at the strategic, tactical and operational levels. TAM programs commonly focus on the changes required and less on how to successfully implement the change. Understanding the potential challenges and learning how to use the agency’s support mechanisms are essential to advancing TAM improvements within the agency.

Building a TAM Organization

Agency leadership and TAM program man¬agement have extra roles to play as communicators, advocates, mentors and change agents. They may require extra tools to help them fulfill their roles, and even to cope with the TAM initiated changes.

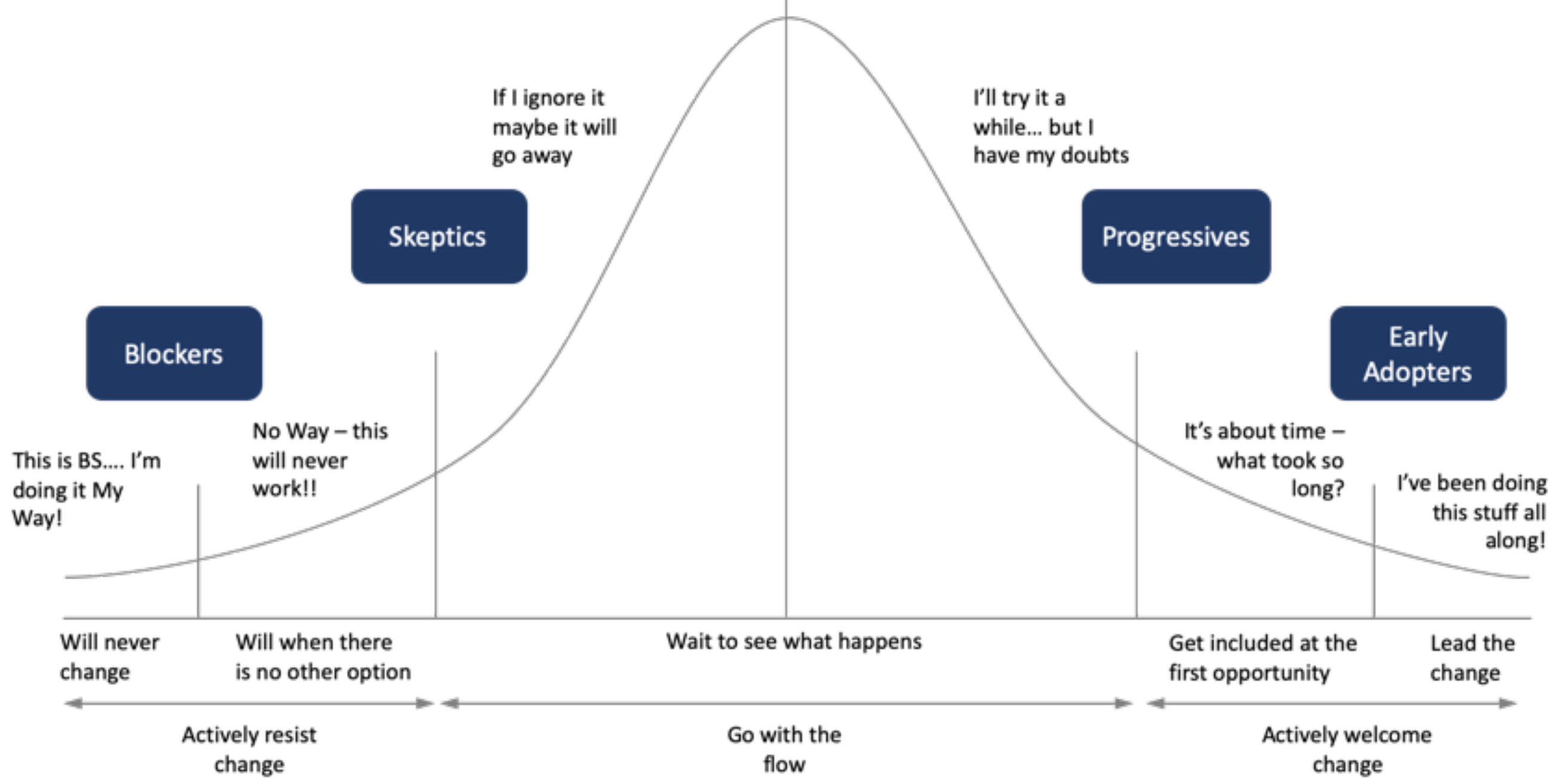

People tend to have similar reactions to any change that will challenge the status quo. Those in favor of the TAM program changes, or those more adaptable to change, may more quickly move through the process of transitioning to new and improved ways of doing things. Figure 3.2, An individual’s response when presented with change, illustrates the range of receptivity to change and how to understand it so that it can be planned for.

TIP

Implementing TAM or improving TAM business processes involves changing the way the agency conducts business. It involves people, processes, and/or technology. TAM improvement is a change process so it should involve change management techniques.

Managers need to be equipped to advance more quickly so they can fulfill their support role successfully, even while they themselves are experiencing the effects of the changes the asset management program is implementing.

Managers need to be equipped to advance more quickly so they can fulfill their support role successfully, even while they themselves are experiencing the effects of the changes the asset management program is implementing.

Asset Management Early Adopters

These are members of the organization who are already prepared to adopt asset management best practices, have been advocating for it in the past and are ready to see the change happen.

What They Need

- Communication channels that are targeted to manage expectations and minimize frustration

- Pilot projects that have good asset data, and can better model and inform tactical and strategic decision-making

- Opportunities to showcase early wins in the TAM transition

Asset Management Progressives

Asset management progressives are predis¬posed to see TAM as a change for the better. They see asset management as a good idea, are willing participants in the change, but need to understand the objectives and what the future will look like.

What They Need

- Communication channels that report on progress and highlight expected future improvements

- Training and reinforcement that emphasizes how they can help implement the change and how their own role may change

Asset Management Skeptics

Skeptics are predisposed to see TAM as a change for the worse. They are wary of proposed changes, and feel existing processes are effective and do not need to be “fixed.” Messaging targeted to (or delivered by) Progressives will alienate this group and increase resistance.

What They Need

- Much more detail on how the TAM Program will be implemented and why the change is necessary

- Process mapping and other group activities that highlight where problems exist

- Once they are convinced that change is required, they will benefit from training

Asset Management Blockers

TAM Blockers are strongly attached to existing processes and will resist change. These individuals will take the longest amount of time to adjust. Some may never be able to make the change, and may choose to leave the agency if the change is implemented.

What They Need

- Understanding of the root cause of their resistance, which may be related to a loss of control, status within the agency, or loyalty to past managers or staff

- Communication targeted to help them realize that TAM Program improvements within the agency are necessary.

- Activities or celebrations that recognize and acknowledge the foundational aspects of past good work over the agency’s history

New Brunswick DTI

Despite a long history and legacy of existing practices and a strong internal institutional resistance to change, New Brunswick Department of Transportation and Infrastructure (NB DTI) implemented Lean Six Sigma to better document existing practices and identify where improvements could be implemented for savings or service improvement. This helped advance and effect change. Over time, the program included increased efficiency, cost savings, refined procurement methods, and application of asset management decision-making to pavements, bridges, culverts, facilities and other transportation infrastructure. The use of methodologies like Lean Six Sigma can aid agencies with a focus on change management.

Michigan DOT

When introducing a Maintenance Rating System, Michigan DOT (MDOT) started the change management process early in the project. Agency leadership was consistent and passionate throughout the project. The process was developed with involvement from individuals within each Region, including people in leadership as well as those on maintenance delivery teams. These discussions identified opportunities for consistency and enabled development of a system that represented actual performance and decision making.

The Maintenance Rating System was piloted within one Region that was most proactively seeking the information that the system provided. This enabled any kinks to be ironed out in the system and also developed individuals within MDOT who could train their peers in the system, results, analysis and opportunities for decision making. It also provided data that enabled the Regions to learn from the results, make a change in investment and improve the maintenance level of service delivered. The rating system was named the “Michigan Maintenance Rating System (MiMRS).”

During implementation MDOT identified a specific roles for coordinating and driving the system, and identified individuals within each Region that had shown interest in the system and competency in analytical assessment to be part of a user group to share knowledge and disseminate information. MDOT also shared the results and news stories internally to enable peer comparison and drive consistency. Leadership identified specific funding for projects developed based on the maintenance rating system results.

This process change was part of a broader MDOT approach to Performance Based Maintenance that included implementing a new inventory and maintenance management system. Performance Based Maintenance will enable MDOT to better understand their assets, the cost of maintenance and the cost to make improvements to asset functionality. The goal of Performance Based Maintenance at MDOT is to achieve a needs-based budgeting approach to non-winter maintenance and enable better decision by supervisors and management.