- Chapters

-

Chapter 6

Sections - Chapter 6 Home Page

- Chapter PDF

Chapter 6

Quick Links

6.5.2

Monitoring TAM Processes and Improvements

As discussed throughout this Guide, TAM is an on-going process that needs to be monitored regularly to ensure that it continues to support an agency’s business decisions. This section presents tools and methodologies used to accomplish this. It also builds on the application of some of the tools introduced in section 2.5.1, Assessing Current Practice.

Gap Assessment

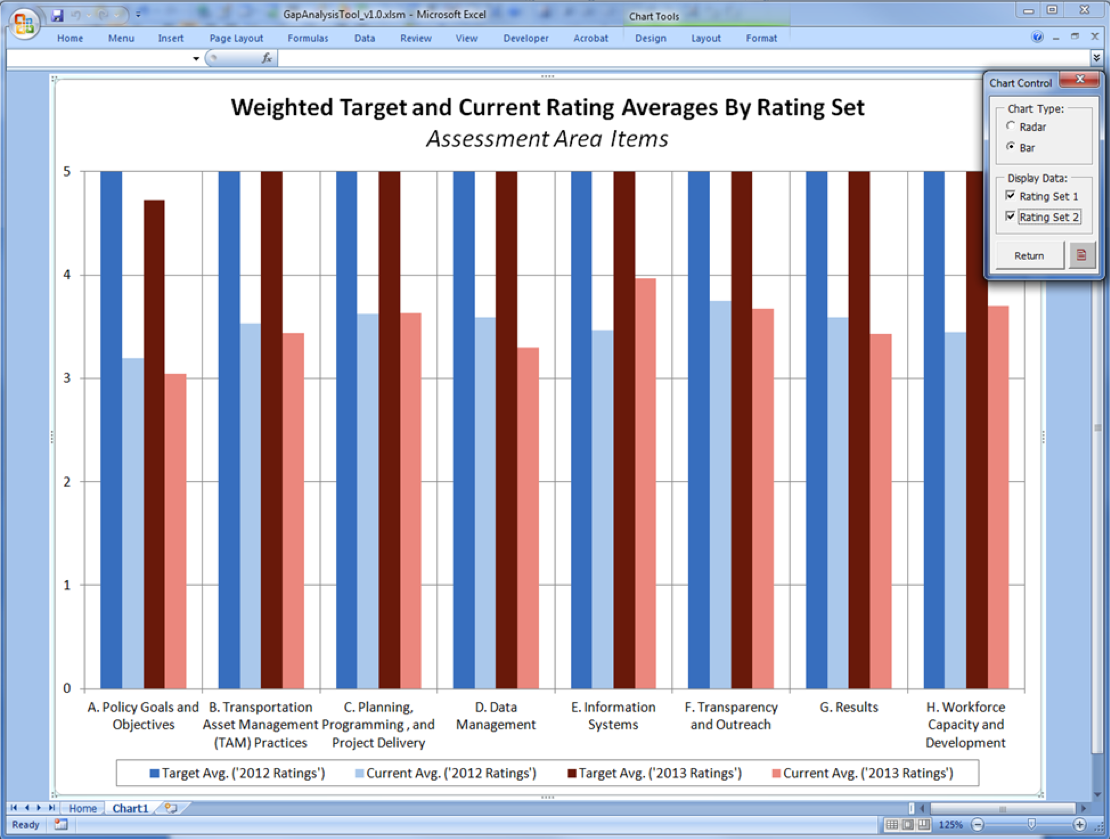

A gap assessment is used to identify differences, or gaps, between an agency’s practices with those suggested as part of an established asset management framework. The results of a gap assessment can be used to identify changes in business processes that are needed or can serve as the basis for developing priorities as part of an asset management implementation plan. The gap analysis tool available through the AASHTO TAM Portal is an example of a tool that can be used by an agency to assess practices so they can be compared to desired, or more established, practices. A summary of the gap analysis tool and other frameworks for assessing current practice was presented in Figure 2.6. An example of a chart showing targeted and current ratings in eight assessment areas over a 2-year period is presented in Figure 6.6. While the agency’s targeted, or desired, scores remained consistently at a rating of 5 over both years, the graph is helpful for determining what assessment areas have improved over the 2-year period and which have not.

Figure 6.6 Example Comparing Assessment Area Scores from Two Different Rating Periods

Source: AASHTO. 2015. Transportation Asset Management Gap Analysis Tool User Guide

TAM Webinar #29 - Process Improvements

Lean Six Sigma

A lean six sigma framework uses statistical analyses as part of a continuous improvement approach to evaluate the cause of defects and methodically make improvements to processes to eliminate them. Six sigma is widely used in manufacturing sectors, but can also be applied to many TAM functions. For instance, a six sigma analysis would be useful in analyzing the root cause of defects associated with a poorly-performing asset. Combining a six sigma approach with a Lean framework, which focuses on reducing waste, can help agencies develop more efficient and sustainable processes.

New Brunswick DTI

The New Brunswick Department of Transportation and Infrastructure (NB DTI) implemented Lean Six Sigma to better understand and document existing practices and identify where improvements could be implemented for savings or service improvement. The Lean Six Sigma methodology helps to improve performance through a collaborative process that systematically removes waste and reduces variation while improving customer satisfaction. For NBDTI, the application of this methodology has resulted in increased efficiency, cost savings, refined procurement methods, improvements to delivery of operational programs and services, and has supported the application of asset management decision-making to pavements, bridges, culverts, facilities and other transportation infrastructure.

ISO 33000 Process Assessment

The International Organization for Standardization (ISO) has introduced a variety of processes to support Asset Management. ISO 33000 is a standard for Process Assessment, providing a structured approach to help agencies better understand their processes, evaluate the suitability of their existing practices, and to determine the suitability of another organization’s processes as a way of improving practices.

TAM Webinar #63 - Consistency Reporting

The Balanced Scorecard

The Balanced Scorecard approach was initially developed to enable organizations to make complex tradeoff decisions that balanced different types of performance criteria. For example, the framework could be used to help determine the tradeoff between improving the level of service provided in a corridor with improving environmental sustainability on a statewide basis. The balanced scorecard analysis takes a holistic and balanced approach to these types of issues, by simultaneously evaluating competing and dissimilar needs (such as Customer Satisfaction, Sustainability, and Safety). The advantage to the balance scorecard approach is the fact that multiple measures are considered, rather than a single set of measures that might disregard an important factor in the decision. The results produce a rational set of investment decisions that considers all of the factors that the agency views as most important to the final selection.